- This topic is empty.

-

AuthorPosts

-

2025-02-24 at 2:46 pm #3029

In industrial automation and control systems, the drive valve interlock system is a key component to ensure the reliable operation of the system. The system controls the operating sequence of the valve through an interlocking device, thereby preventing misoperation or accidental operation and ensuring the safety and efficiency of the equipment. To ensure the effectiveness and operational reliability of the drive valve interlock system, it is crucial to install it correctly. This article will provide you with a detailed installation guide to help you avoid common errors during the installation process and ensure the long-term stability of your system.

1. Overview of drive valve interlock system

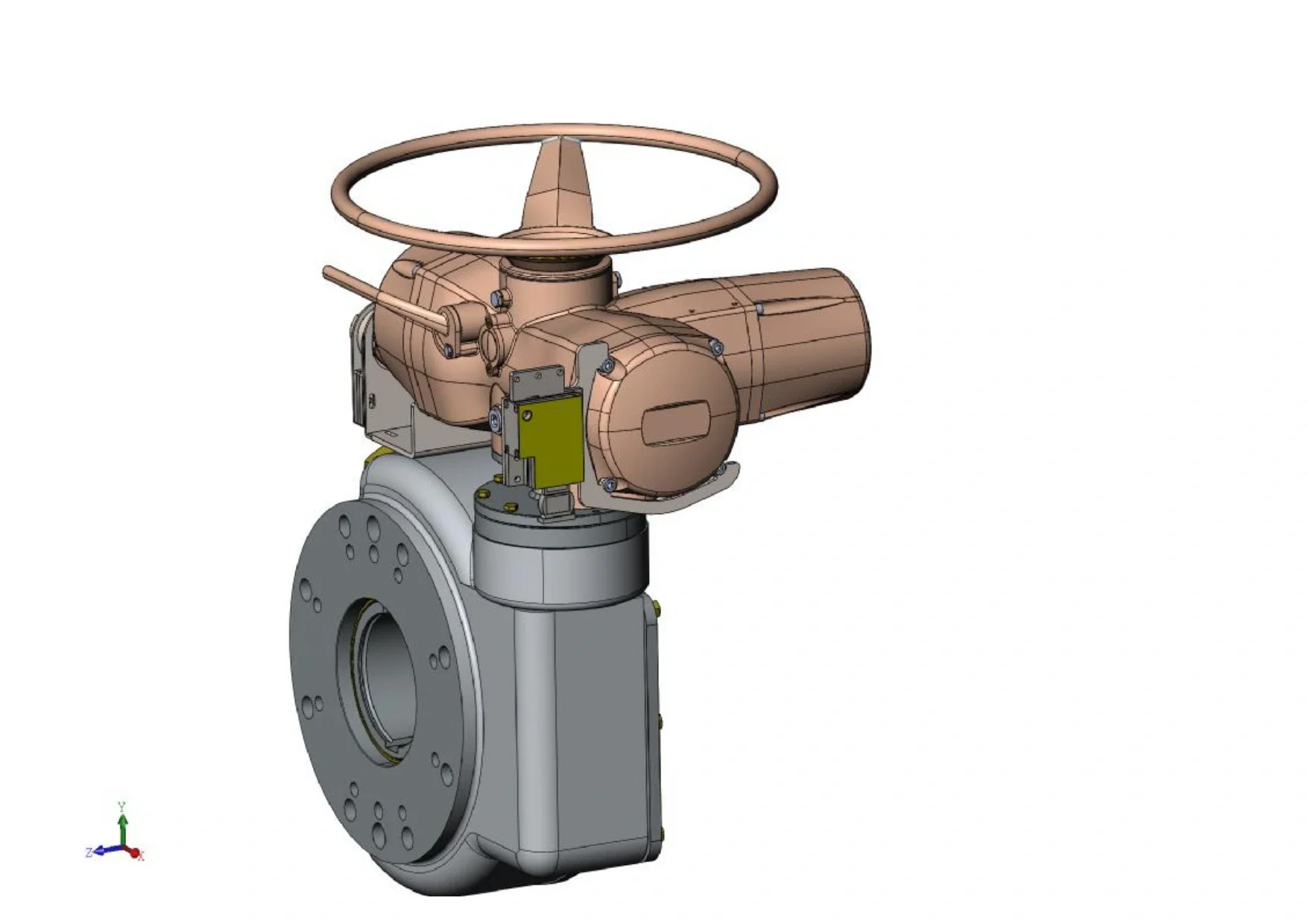

Drive valve interlock system is a mechanical or electronic control device that is usually used in industrial fields such as piping systems, hydraulics, and pneumatic equipment. The basic function of this system is to ensure that the valve can only be opened or closed in a specific order by setting the interlocking relationship between multiple valves under certain operating conditions. This interlocking mechanism can effectively prevent safety accidents caused by operating errors, equipment failures, or external factors, greatly improving the reliability of the system.

2. Working principle of drive valve interlock system

The drive valve interlock system realizes the interlock control of the valve through mechanical devices. The system is a mechanical safety system that is artificially set up to prevent human errors. It must operate in the specified order, otherwise subsequent operations cannot be performed.

The interlocking system uses mechanical interlocking devices with a key encoding system to ensure that the operator opens, closes, or isolates the corresponding safety facilities according to the predetermined procedures.

The installation quality of the drive valve interlock system directly affects the operating reliability and security of the entire system. Improper installation will not only cause system functions to fail, but may also cause equipment failure, production stagnation and even safety accidents. Therefore, during the installation process, relevant technical standards and operating procedures must be strictly followed to ensure that the drive valve interlock system can run normally and efficiently.

3. Drive valve interlock system installation preparation

Equipment inspection: Before installing the drive valve interlock system, you must first conduct a comprehensive inspection of all relevant equipment in the system to ensure that all components are intact and meet technical requirements. Especially when selecting drive valves and interlocking devices, it is necessary to ensure that their specifications and models match the requirements of the piping system.

Determine the installation location: When installing the drive valve interlock system, a reasonable installation location is very critical. The interlocking device needs to be closely coordinated with the valve and can be easily operated and maintained. Generally, it is recommended to choose a location that is easily accessible and not disturbed by external factors. For electronic interlocking systems, the layout of the power supply and signal lines should also be considered.

Confirm the operation sequence: The core function of the drive valve interlock system is to control the operation sequence of the valve. Before installation, the operating sequence of the valve needs to be determined according to the actual working conditions and the correct parameters in the interlocking device. Different systems may have different operating sequence requirements, so the installer needs to communicate with relevant engineers or technicians to ensure the accuracy of the operating sequence.

4. Installation steps of drive valve interlock system

Step 1: Install the valve

When installing the drive valve interlock system, the valve is first necessary. According to the system design drawings, install the valve into the piping system in the correct direction and position. Make sure the valve is installed firmly and closely connected to the pipes to avoid water or air leakage.

Step 2: Install the interlocking device

Next, install the interlocking device. The interlocking device is usually composed of a drive device, a mechanical interlocking mechanism, and a transmission device. During installation, you need to select the appropriate interlocking method according to the system requirements and install the interlocking device in the designated position according to the system design drawings.

Step 3: Debug the interlock function

After the installation is completed, the drive valve interlock system needs to be debugged. During commissioning, firs,t make sure that the operating sequence of all valves is consistent with the predetermined plan, and then check whether the interlocking device can adjust the opening or closing of other valves according to the change in the state of the valve.

When debugging, you need to pay special attention to the following points:

Check the operating flexibility of the interlocking device to ensure that it can respond to valve status changes in a timely manner.

Check the sealing of the valve to avoid leakage affecting the normal operation of the system.

Ensure that all components of the system (such as sensors, actuators, etc.) can work in a coordinated manner.

Step 4: Testing and Verification

After debugging is completed, a comprehensive test of the drive valve interlock system is required. By simulating different operating conditions, verify whether the interlocking function of the system is normal and ensure that the valve can only operate in a predetermined order.

Special attention should be paid to the following aspects during testing:

Whether the system can effectively prevent incorrect operations.

In the event of a fault or abnormal situation, will the system be able to take emergency measures?

Whether the system's response time meets the requirements and avoids security risks caused by operation delays.

5. Maintenance and maintenance of drive valve interlock system

In order to ensure the long-term and stable operation of the drive valve interlock system, regular maintenance and maintenance are very important. Here are some common maintenance measures:

Regular inspection of equipment: Regularly check various components of the drive valve interlock system, especially key components such as valves, interlock devices and sensors, to ensure they are free of wear, corrosion or failure.

Cleaning interlocking device: Clean dust, dirt and other debris inside the interlocking device to avoid these substances affecting the normal operation of the system. For electronic interlocking devices, damage to circuits and components should be avoided during cleaning.

Replace worn parts: Replace easily worn parts (such as seals, drive devices, etc.) regularly to avoid degradation of system performance due to aging of components.

Proper installation and maintenance of the drive valve interlock system is a critical step in ensuring the operational reliability of industrial automation systems. By following the installation guide above, you can maximize your system's stability and security. Regular inspection and timely repair of equipment are also important means to ensure the long-term and efficient operation of the system. Only by ensuring that every link is done in place can the drive valve interlock system play its greatest function and ensure the safety and efficiency of production.

http://www.nudango.com

Shanghai Nudango Safety Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.