- This topic is empty.

-

AuthorPosts

-

2024-12-30 at 2:38 pm #2745

In modern manufacturing, the demand for product diversification and personalization is increasing, and traditional production models find it difficult to cope with the ever-changing market demand. In order to solve this problem, more and more manufacturers have begun to adopt flexible assembly systems. This system is highly adaptable and flexible, and can quickly adjust the configuration of the production line under different products and different production batches to meet diverse production needs. However, the applicability of flexible assembly systems for assembly tasks of complex products is still a question worth exploring.

1. Definition and advantages of flexible assembly systems

Flexible assembly systems are highly adaptable automated assembly systems that can be quickly adjusted according to product changes and production environment requirements. Compared with traditional dedicated assembly lines, flexible assembly systems adopt modular design, have high flexibility, and can support the simultaneous production of multiple types and specifications of products. Its core advantages include:

Quick adjustment of production lines: The flexible assembly system can quickly adjust the configuration of the production line according to different product requirements and production plans, and can even make real-time adjustments during the production process.

Diversified product assembly capabilities: The system can support the assembly of products of different types, structures, and complexities, especially for small batch and multi-variety production environments.

Improve production efficiency: Through intelligent control systems and automation equipment, flexible assembly systems can greatly improve production efficiency, reduce manual intervention, and reduce production costs.

Reduce downtime: Flexible systems can reduce system switching and production line downtime and improve equipment utilization through automated and highly integrated control systems.

2. Characteristics and challenges of complex products

Before discussing whether flexible assembly systems are suitable for complex product assembly, we first need to clarify the concept of "complex products". Complex products usually have the following characteristics:

Multiple parts and high precision requirements: Complex products are often composed of multiple components, and the size, shape, material, and other requirements of these components are relatively complex, and the assembly process requires strict precision control.

Multi-process assembly: Due to the complexity of the product structure itself, the assembly process involves multiple processes, and the operation requirements of each process are different, requiring precise operations.

High customization requirements: In many industries, complex products often need to be customized according to the personalized needs of customers, which increases the complexity and uncertainty of production.

Requirements for assembly sequence and methods: The assembly of complex products often requires specific assembly sequences and methods, which makes assembly systems with higher flexibility requirements face greater challenges.

Based on the above characteristics, the assembly of complex products faces many challenges:

Assembly accuracy issues: Complex products usually have strict requirements for accuracy, and any slight error may cause the product function to fail to meet the standards, or even cause the entire assembly process to fail.

Multi-process coordination: Complex products usually involve multiple processes and steps, and different processes require precise coordination and synchronization. Any error in any link may lead to overall assembly problems.

Assembly time problem: The assembly time of complex products is long, requiring more manual intervention and complex mechanical assembly.

3. Application of flexible assembly system in complex product assembly

Whether the flexible assembly system can be effectively applied to the assembly of complex products depends on whether it can overcome the above challenges and provide sufficient flexibility and precision. The following are the application advantages of a flexible assembly system in complex product assembly:

Automation and high-precision control

Modern flexible assembly systems can greatly improve assembly accuracy by integrating high-precision sensors, robots, vision systems, and automation tools. For the assembly of complex products, the system can use visual recognition technology to accurately locate parts and components to ensure that every detail in the assembly process meets the design requirements. In addition, the robot arm can perform high-precision operation tasks to ensure the correct assembly of complex parts and avoid errors that may occur in traditional manual assembly.

Multi-process parallel operation

The flexible assembly system can realize multi-process parallel operation, especially when dealing with complex products. Through modular production units, different workstations can perform different assembly steps at the same time. This parallel operation mode can greatly improve production efficiency and shorten the overall assembly time. For example, when producing a complex electronic device, the assembly system can handle the installation, welding, debugging, and other processes of different parts at the same time, and each step can be adjusted and optimized as needed.

Real-time monitoring and intelligent adjustment

With the advancement of intelligent manufacturing technology, modern flexible assembly systems can not only monitor in real-time but also adjust the production process in real-time through data analysis. The system can detect the assembly status of parts in real-time based on the data of sensors and visual systems, and make necessary adjustments through feedback mechanisms. This intelligent adjustment capability is crucial in the assembly of complex products because it can quickly respond to any problems that may arise during the assembly process, avoiding the uncertainty and errors in traditional manual operations.

Flexible configuration and high adaptability

The flexible assembly system is highly adaptable and can quickly switch between different assembly tasks. For complex products, it is often necessary to adjust according to different product designs and production batches. The flexible assembly system can adjust the work content and steps of the production line according to actual needs, and even partially replace or correct them during the assembly process. This flexibility makes the production of complex products more efficient and operational.

Adapt to small batch customized production

The customization requirements of complex products are high, and many companies need to produce small batches according to customer needs. Flexible assembly systems can adapt to small-batch production modes, and quickly switch assembly tasks for different products through modular design and intelligent scheduling. Compared with traditional dedicated production lines, flexible assembly systems are more efficient in small-batch production and can meet personalized customization needs.

In general, flexible assembly systems have great potential and advantages in the assembly of complex products. It can overcome many challenges in the assembly of complex products and improve production efficiency and product quality through technologies such as automation, high-precision control, and intelligent monitoring. At the same time, its high adaptability and flexibility also enable it to cope with customized and personalized production needs.

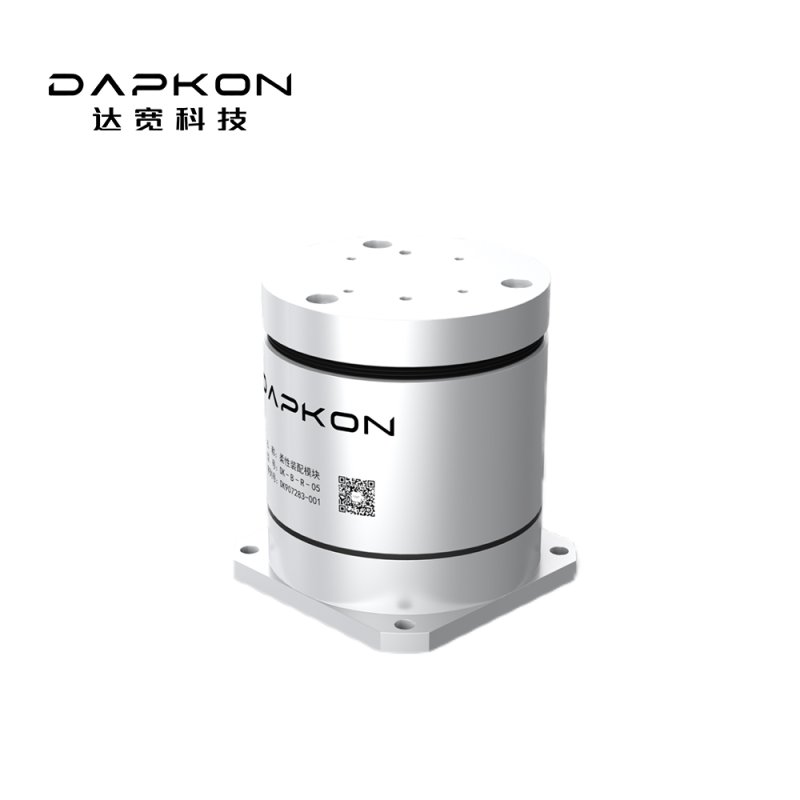

As a professional flexible assembly system supplier, our flexible assembly system combines advanced automation technology, intelligent control, and high-precision equipment to accurately respond to the assembly needs of a variety of complex products, helping companies cope with increasingly complex market demands and production challenges.

http://www.dapkon.ai

Shanghai Dapkon Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.